![]()

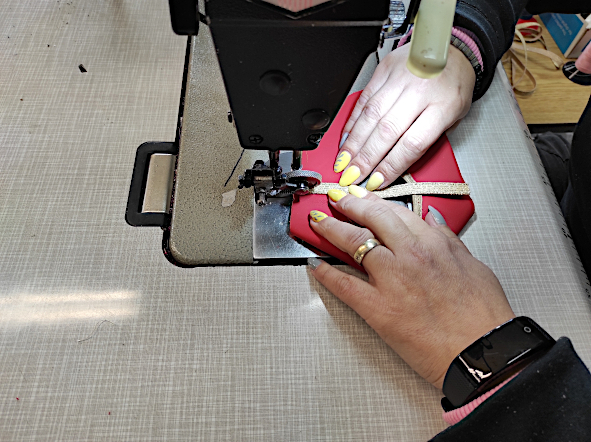

All slippers in our range are the result of our own development and years of experience in footwear production (a family tradition since 1976). The entire production process is organised and carried out in Slovenia. The design and organisation of the production are both managed in such a way that the risk of customer complaints is reduced to minimum. The entire production process is monitored as is the quality of individual phases of production. Our employees are trained and motivated all the time in the sense of detecting defects during different stages of production on their own initiative. Apart from what has already been said, another advantage of domestic production is flexibility and responsiveness to market needs. Yet we also make tailor-made products which is something global producers do not offer. Apart from a skilful pair of hands, the final quality of the product also depends on the selection of quality materials and raw materials. For the needs of our production we purchase materials exclusively on the EU markets making it our practice to choose trusted suppliers who provide the best quality-price ratio. Italians are known as producers of the best leather. Consequently, we buy the leather from them as well as from northern European countries. Materials used for soles are of Slovene and Italian origin. Quality and innovative raw materials which are not visible on final products are also of extreme importance to produce quality footwear. Such raw materials include various adhesives, thread, intermediate technical materials… These too are supplied by well-established EU producers.